Mastering Particles

“From detergents to Mars missions”

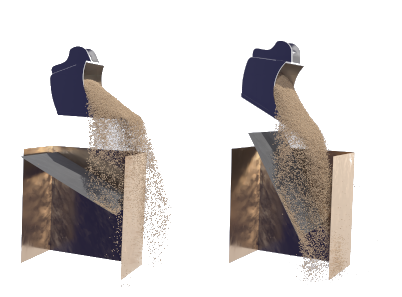

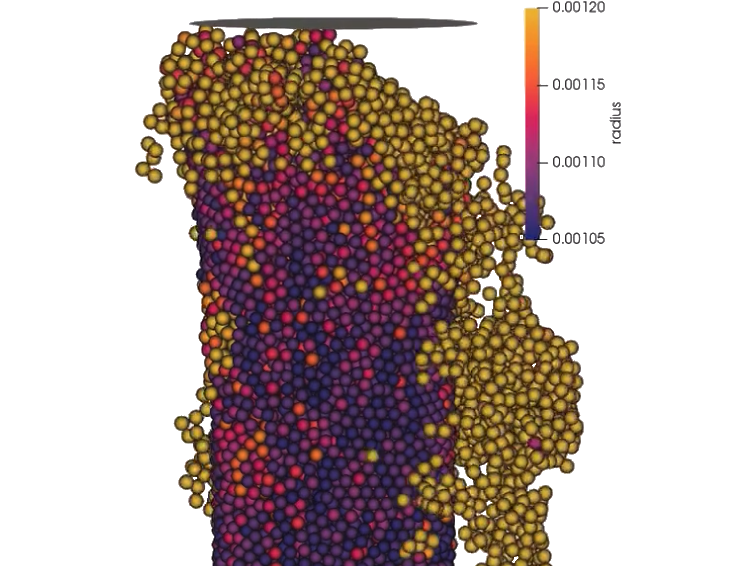

Our Discrete Element Method (DEM) simulation software fuels innovation for everyone, improving particle products and processes to be more cost-effective, more sustainable, safer and unique.

Our Discrete Element Method (DEM) simulation software fuels innovation for everyone, improving particle products and processes to be more cost-effective, more sustainable, safer and unique.

We are pleased to announce that the 5th Aspherix® & CFDEM® Conference will be held in Vienna, Austria on: 26-27 September 2024. This is another exciting opportunity for the DEM and CFD software user community to make new international connections, exchange knowledge, see interesting presentations, take part in lively discussions and an overall enjoyable experience! Click on the link below for further information and registration.

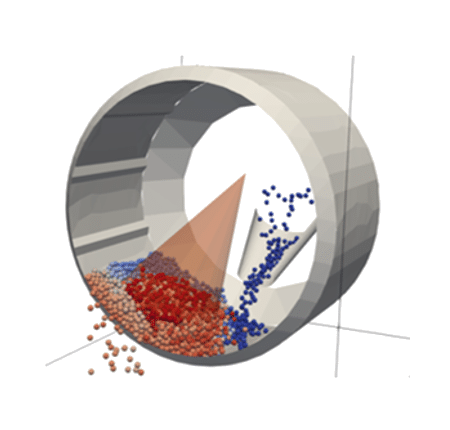

P&G has been using Aspherix simulation software technology for the past eight years for modeling particulate processes via Discrete Element Method (DEM).

Dr. Christopher Stoltz

Procter & Gamble

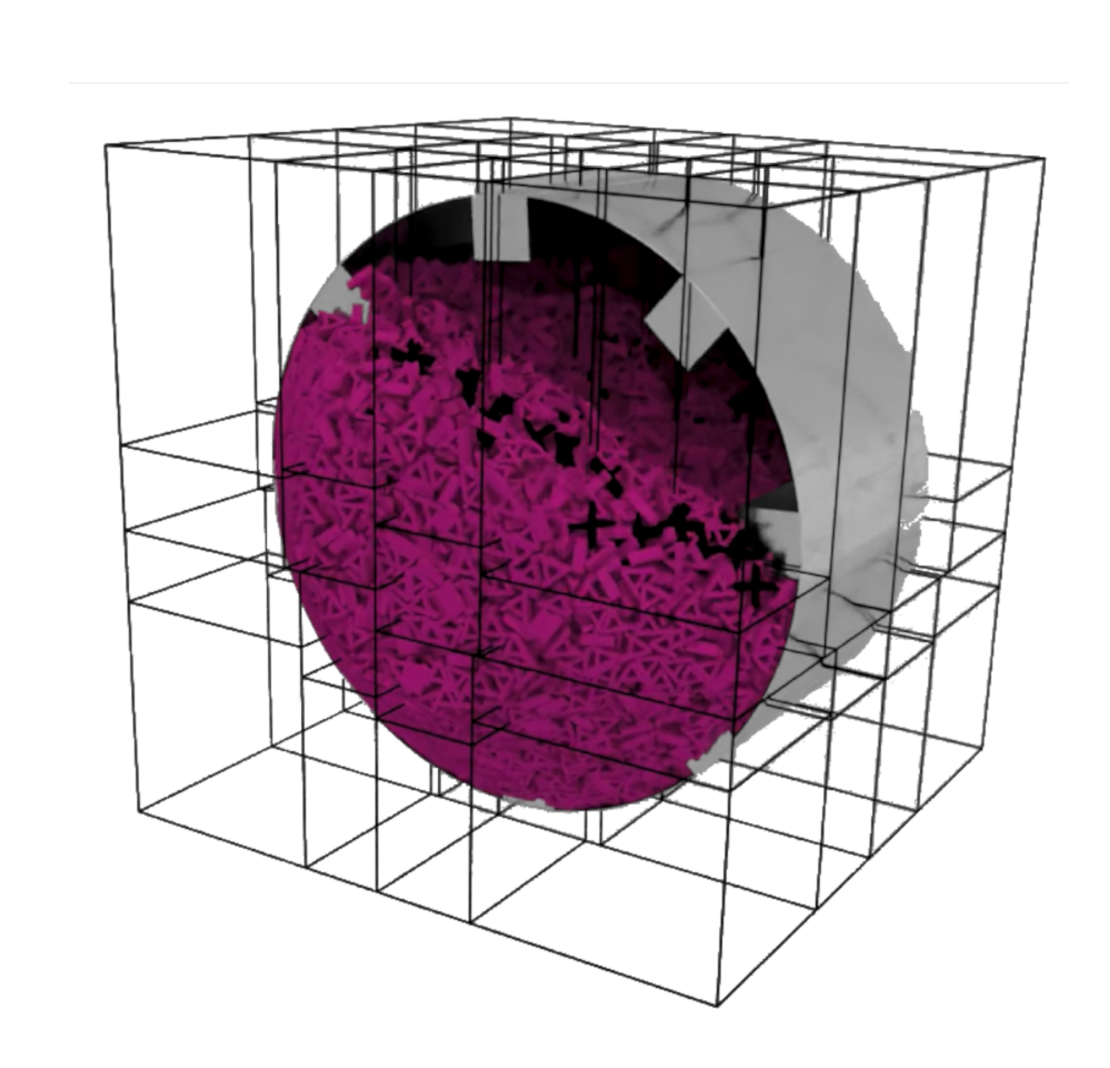

We partner with DCS Computing to develop numerical methods and enhance our understanding of pharmaceutical unit operations, provide tools for optimization and approaches to minimize the risk of failure during the development of manufacturing processes to create novel medicines for our patients.

Dr. Martin Lubej & Dr. Maximilian Eggersdorfer

Novartis AG

We profit from close collaboration with DCS Computing GmbH on the development of an innovative simulation model that helps us advance in computational process engineering. We appreciate their capacious expert knowledge and strong technical support.

Dr. Markus Klinsmann

Robert Bosch GmbH

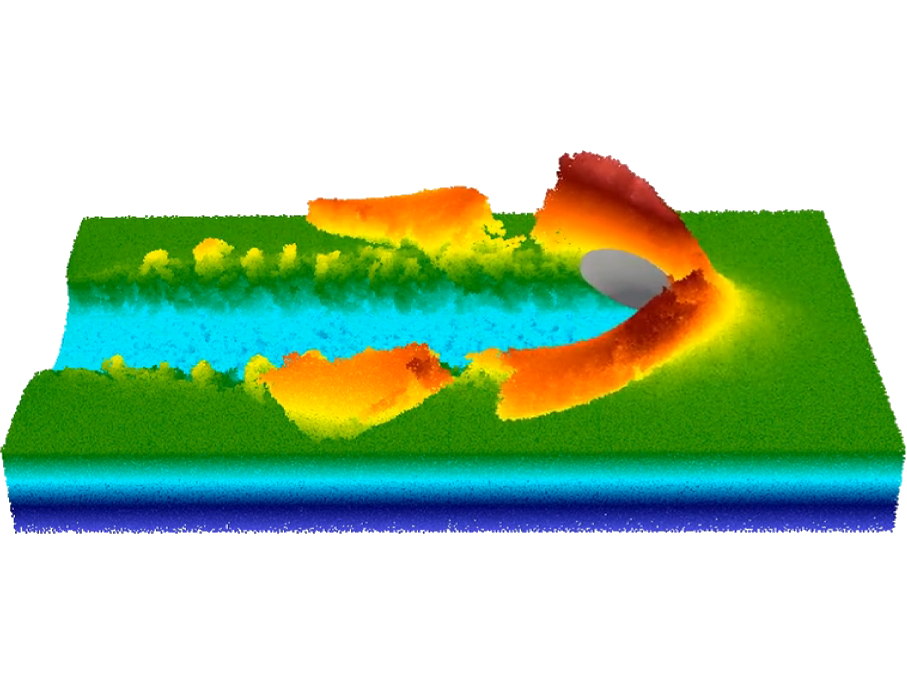

Discrete Element Modelling is an essential tool for planetary exploration as well as preparation and development of future missions.

DLR collaborates with DCS since more than ten years and in several projects covering planets like Mars as well as small bodies like asteroids. We enjoy DCS’s exceptionally high degree of professionality and enthusiasm when it comes to DE modelling. DCS takes the challenge to push DEM to new extraterrestrial applications.

Dr. Marco Scharringhausen

DLR | German Aerospace Center

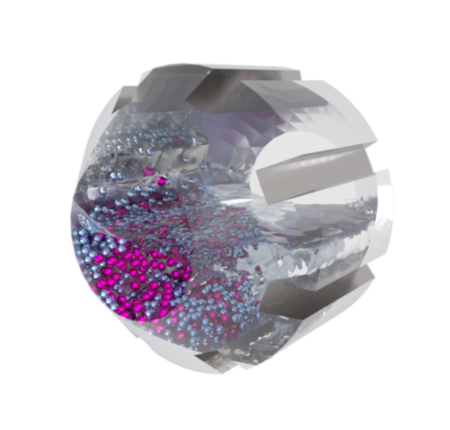

Competences, technologies and excellent services of DCS Computing offers us tailor made simulation capabilities to study complex phenomena in process engineering and plastics industries.

Dr. Harald Herbst

Borealis Polyolefine GmbH

DCS are one of our official suppliers for a project aiming to develop computational techniques to model waterborne plastic based on the Digital Twin process using Aspherix and CFDEMcoupling. We value the teams high-level of technical support, expertise and professionalism and we look forward in continuing to working closely together towards the success of this project.

Dr. Bruno Sainte-Rose

The Ocean Cleanup

Visit the Testimonials page for more!

Aspherix® has numerous cutting-edge physics models and great options for integration.

In Japan our esteemed distribution partner CAE-SC is in charge of sales and support activities.

No posts found!